1. The role of the reed

The function of the reed is to determine the density

of the warp wires and the width of the net, to guide

the sword belt through the weaving mouth, and to

beat the weft wires towards the weaving mouth to

complete the weft beating movement.

2. Technical requirements of the reed process

(1) Reeds should be straight, evenly arranged, clear

and bright between the reed teeth, no soft pieces,

bruises, scratches.

(2) The reed surface of reed blade and tie wire is not

allowed to have corrosion phenomenon, the surface

is smooth without cracks and burrs, the edges are

not allowed to have sharp edges and corners, and

the reed surface is flat without high and low teeth.

(3) Reed density and the range of large reed holes

are measured and tested in accordance with product

technical requirements.

3. Types and structure of reeds

There are three kinds of reeds: welded reed, adhesive

reed and combination reed. Among the welded reeds,

there are tin-welded reeds and plastic-welded reeds,

and most of the domestic wire mesh is commonly used

as adhesive reeds.

A glued reed is a wire that is evenly wrapped between

two reed edges and coated with a layer of adhesive glue,

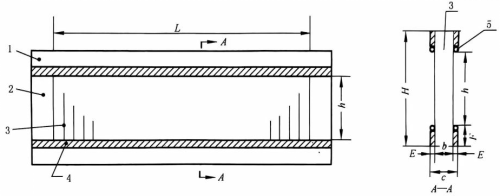

as shown in Fig. 3-9.

b -- reed width; c -- full width; h -- working height; L -- working length; H -- full height;

1 - Reclining Frames (ExF); 2 - Standing Frames; 3 - Reeds; 4 - Ties; 5 --Half Dollar Iron.