Technical Details

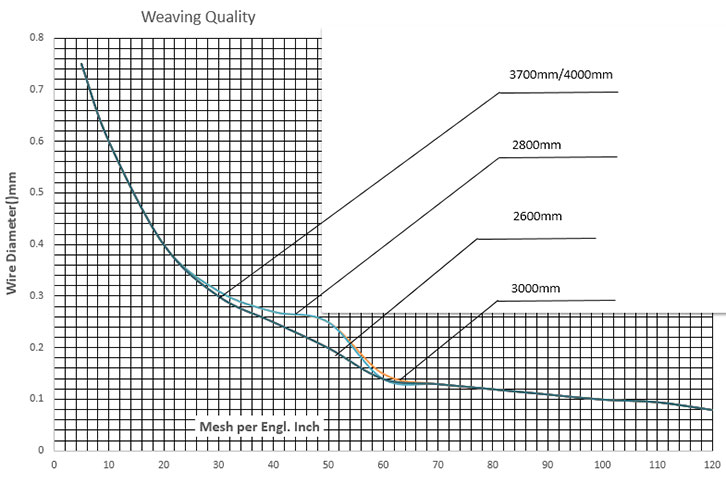

Weaving Range: 10 to 80mesh per inch, special equipment down to 5 and up to 200mesh per inch by the supply of change wheels for the regulators

Full PLC control equipment is to do 0-200mesh freely.

Wire Diameter: up to 0.8mm

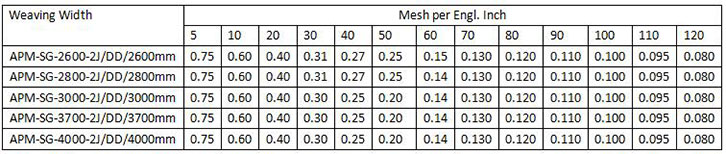

For accurate wire diameter range see the chart

Weaving Width: 1000mm up to, with strengthening for still large widths.

Kinds of Weaving: Plain weaving and with extra equipment four-shafts twill

Wire Material: Iron, stainless steel, spring steel, copper, brass, bronze, aluminum, plastic asbestos.

Picking Speed: adjust freely by the frequency see chart

Drive: by electromagnetic motor making about 950r.p.m. (motor output according to width, see chart). Friction clutch with four V-belts 17x11; if desired equipment with geared flywheel clutch for power return of slay.

Beaming Drive: by worm gears through servo motor

Beaming Speed: about 25m/min (82ft)

Stopping Devices: on warp and weft, primary connection 220 volts A.C., 50 cycles, secondary 24 volts.

Weaving Reed Measurements:

Overall height: 90mm

Reed slot: 10mm & 12mm with the thickness 1.6mm plate

Maximum reed length: about weaving width +60mm

Heddle Measurements: Hole centre distance: 200mm. Heddles nos. 2 and 4

Heddle frame Plates:Nos. 2 and 4

Weaving Specification in Plain Weave

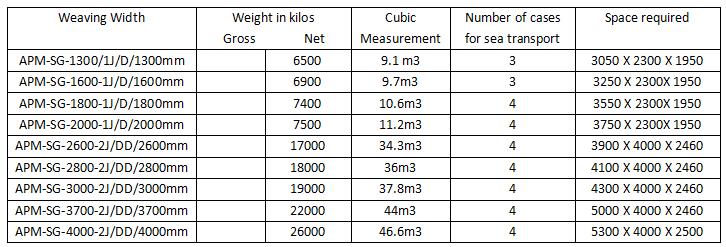

Weights and Case Measurements

The figures indicated are for standard designs and may be increased for special equipment.

Lustrations, drawings, measurement and weight indications are without engagement and subject to modification.