1) A wire is pulled on each side of the net as a warp straight line reference, which is not threaded through the crossbar, not through the heddle, but through the reed, and is pulled tightly from the back beam to between the breast rolls.

2) When weaving plain nets, the weaving machine stops at the time of the twist, observe whether the relative position of the warp position line and the warp straight line meets the requirements, if not, adjust the length of the tappet to make the heald rise and fall by a certain size, until it meets the requirements. When the tappet is adjusted long, the position of the heald rises, and when it is adjusted short, the position of the heald falls.

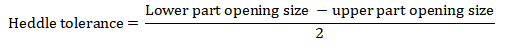

3) Heal height adjustment when weaving twill nets: Since the weaving machine does not have a flat heald device, the 4 healds cannot be in a flat state on the machine, so when adjusting the height position of the healds, it is only possible to adjust them according to the position of the opening state. Adjustment method: First pull a warp straight line on both sides of the fabric edge. Then observe the position of the warp straight line in the opening. The warp straight line divides the opening into upper and lower parts. If the upper part of the opening is larger than the lower part of the opening, it is judged to be a high heald; if the upper part of the opening is smaller than the lower part of the opening, it is judged to be a low heald; if the upper part of the opening is equal to the lower part, it is judged to be a flat heald. The dimension of the warp position line leaving the warp straight line can be calculated in this way:

Adjust the length of the tappet to raise and lower the heald frames, adjust the height of each heald one by one, and make both sides of the heald meet the process parameters.