The warp wire of the square mesh is subject to varying degrees of bending deformation within the mesh, and the length of the warped warp wire is always greater than the width of the mesh.

The weft shrinkage rate of general metal wire mesh is achieved through the plastic extension of the metal wire woven into the mesh (unlike the warp shrinkage rate, which is met by increasing the warp length). Therefore, the magnitude of the weft shrinkage rate of metal wire mesh directly affects the probability of weft wire fracture within the mesh. The weft shrinkage rate of metal wire mesh is an important structural parameter, providing crucial reference data for estimating the weaving difficulty of metal wire mesh of a certain specification and for selecting weft wire materials and mechanical properties.

In the plain weaving of mesh, under normal circumstances, the weft shrinkage rate is generally less than the warp shrinkage rate. Therefore, the elongation rate of most soft metal wire materials can meet the requirements of weft shrinkage rate.

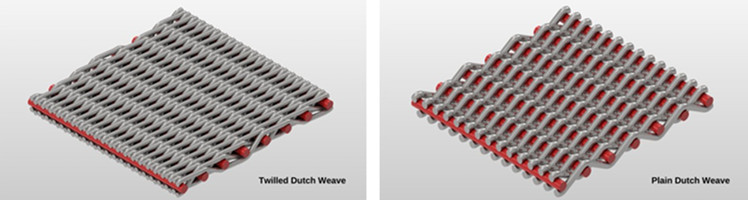

The Dutch weave is made up of thicker warp yarns and finer weft yarns. The warp yarns do not bend or shrink, while the weft yarns bend and deform more within the fabric, resulting in a larger amount of weft shrinkage. The degree of this weft shrinkage directly affects the quality of the woven fabric. Dutch weaves with high weft shrinkage have high tendency to break at the weft points, so calculating the weft shrinkage for Dutch weaves is crucial for optimal weaving quality.