Different specifications of square mesh, due to their different ratio of opening/wire, also have differences in their warp shrinkage. The smaller the opening/wire ratio, the greater the warp shrinkage. For square mesh of the same specification, the thickness of the woven metal mesh also varies due to the different tension of the warp wire used in weaving. They also have differences in warp shrinkage, with thicker meshes having greater shrinkage. That is, the larger the warp crimp angle, the greater the warp shrinkage.

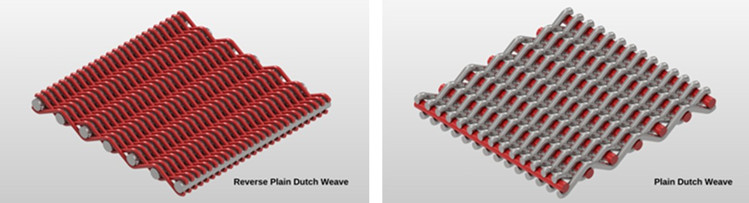

Different weave types of metal wire mesh have significant differences in their longitudinal shrinkage. A plain Dutch weave mesh has no longitudinal shrinkage due to the thicker warp wires, which do not bend within the mesh. However, a reverse plain Dutch weave has a greater longitudinal shrinkage due to thin warp wires, thick weft wires, and a larger warp bending angle within the mesh. With a plain weave mesh, where the warp and weft wire diameters are equal, both warp and weft wires bend within the mesh, but the majority have unequal bending angles, resulting in the warp bending angle being larger than the weft. Consequently, the longitudinal shrinkage of the warp wire is greater than that of the weft wire. As the ratio of aperture to wire diameter increases in a plain weave mesh, the bending angles of warp and weft wires tend to equalize.

Different weave types of metal wire mesh have significant differences in their longitudinal shrinkage. A plain Dutch weave mesh has no longitudinal shrinkage due to the thicker warp wires, which do not bend within the mesh. However, a reverse plain Dutch weave has a greater longitudinal shrinkage due to thin warp wires, thick weft wires, and a larger warp bending angle within the mesh. With a plain weave mesh, where the warp and weft wire diameters are equal, both warp and weft wires bend within the mesh, but the majority have unequal bending angles, resulting in the warp bending angle being larger than the weft. Consequently, the longitudinal shrinkage of the warp wire is greater than that of the weft wire. As the ratio of aperture to wire diameter increases in a plain weave mesh, the bending angles of warp and weft wires tend to equalize.