In order to have a certain granularity and physical and chemical properties, metal powders need to undergo some pretreatment before forming. Pretreatment includes powder annealing, sieving, granulation, and addition of lubricants. Sieving is a commonly used method to determine the particle size of powders, and is suitable for grading and sizing of medium and coarse powders above 40μm. The international standard adopts the Tyler sieve. The mesh size (abbreviated as mesh) is commonly used to indicate the aperture diameter of the sieve and the particle size of the powder. The mesh size refers to the number of mesh holes on a sieve per inch length. As the mesh size is indicated on the sieve frame, it is sometimes referred to as the sieve number. The higher the mesh size, the finer the mesh holes.

Screening operation

Take a certain weight of powder and pass it sequentially through a set of sieves with decreasing mesh sizes, classify it into several levels by particle size, and use the aperture of the corresponding sieve to represent the particle size of each level of powder. As long as the weights of each level of powder are measured, the composition of powder particle size can be calculated using weight percentages.

Mesh standards

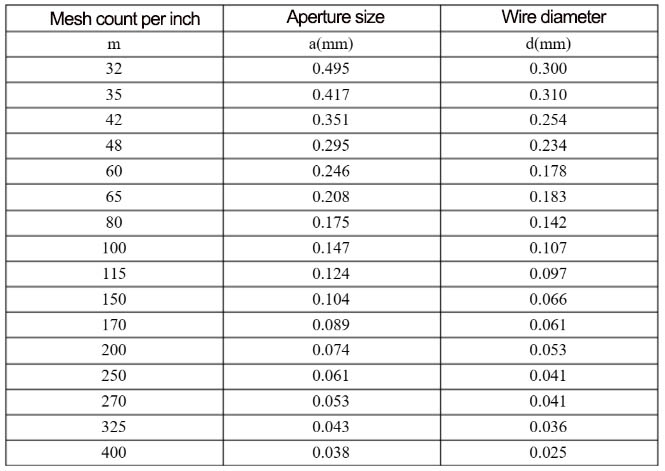

Mesh count refers to the number of mesh openings per inch of screen. The mesh count is generally indicated on the screen frame and is commonly referred to as the screen number. Thus, the higher the mesh count, the finer the mesh openings. The number of mesh openings is related to the diameter of the wire used and the size of the openings. The number of openings per inch is consistent with the number of wires per inch. If m represents the mesh count, a represents the mesh size (in mm), and d represents the wire diameter (in μm), then the following relationships apply:

The Taylor series of sieves is based on a sieve aperture size of 0.074mm with 200 mesh (this sieve is called the base sieve), multiplied by the main modulus of 1.414 to obtain an aperture size of 0.104mm for a 150 mesh sieve. Similarly, multiplying 0.074mm by (n=1,2,3) gives aperture sizes for 150, 100, 65, 48, and 35 mesh sieves, respectively. Dividing 0.074mm by (n=1,2,3) gives aperture sizes finer than 200 mesh for 270 and 400 mesh sieves.

The Tyler sieving method also uses a sub-multiple of 1.189, which is multiplied or divided by 0.074mm to obtain a finer series of mesh sizes. The following table lists the Tyler standard sieve.